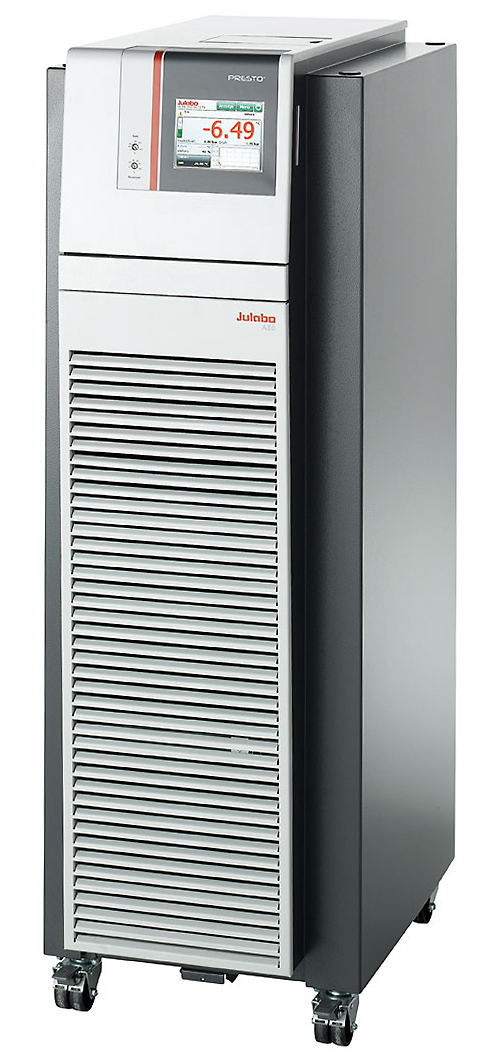

PRESTO W85 Temperature Control System

PRESTO W85

Temperature Control System / Process System

Reactor temperature control, tests for all kinds of substances or temperature simulation – the new PRESTO are made for highly precise temperature control and rapid temperature changes.

PRESTO provide large heating and cooling capacities covering a working temperature range from -92 °C to +250 °C. Highly efficient components allow extremely fast compensation of exothermic and endothermic reactions.

Lab users benefit from high flow rates, constant pressure, and a controlled build-up of pump pressure. Changes in the temperature-control liquid’s viscosity are balanced dynamically. Permanent internal monitoring and self-lubricating pumps contribute to the new PRESTO®’s long service life.

A special feature of the new PRESTO is the integrated 5.7’’ industrial touch screen.

All important information is displayed clearly and concisely enhancing ease of use considerably.

The new PRESTO can be operated intuitively with the tip of your finger.

As the new PRESTO operate whisper quiet, you will hardly hear them in your laboratory. Even high room temperatures of up to +40 °C will not make the new PRESTO sweat. Maintenance-free pumps and drives guarantee operational readiness.

Multiple interfaces permit remote control of the PRESTO® across networks and in superordinated control systems. The Design does away with venting slots at the sides. The required installation space is reduced to an absolute minimum.

Your advantages

- For highly precise, external temperature applications

- Rapid heating and cooling

- Fast compensation of exothermic reaction

- Wide working temperature ranges without changing fluids

- Highest performance with small footprint

- Space-saving design optimizes space utilization in your lab

- NEW 5,7” industrial color TFT touch screen

- well-organized view of important information with unmatched, intuitive user friendliness

- Up to 3 user level with password management

- NEW USB (Host und Device)

- NEW Ethernet

- NEW SD-Card slot

- RS232 / optional RS485 / optional Profibus DP

- Stand-by input

- Filling system accessible from the top

Technical Data

| Order No. | 9421852 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Category | Temperature Control PRESTO | ||||||||||||||||

| Working temperature range (°C) | -85 ... +250 | ||||||||||||||||

| Temperature control | ICC | ||||||||||||||||

| Temperature stability (°C) | ±0.05 ... ±0.1 | ||||||||||||||||

| Setting / display resolution | ±0.01 °C | ||||||||||||||||

| Integrated programmer | 8x60 steps | ||||||||||||||||

| Temperature Display | TFT Touchscreen | ||||||||||||||||

| Heating capacity (kW) | 6 @ 400V; 6 @ 230V; 5.5 @ 208V | ||||||||||||||||

| Cooling capacity (Medium: JULABO Thermal | Ethanol) |

|

||||||||||||||||

| Pump capacity flow rate (l/min) | 35 ... 80 | ||||||||||||||||

| Pump capacity flow pressure (psi) | 6.96 … 46.42 @ 400 V; 6.96 … 46.42 @ 230 V; 6.96 … 43.51 @ 208 V | ||||||||||||||||

| Viscosity max. (cSt) | 50 | ||||||||||||||||

| Pump connections | M30x1.5 | ||||||||||||||||

| Refrigerant stage 1 | R507 | ||||||||||||||||

| Filling volume refrigerant stage 1 (g) | 700 | ||||||||||||||||

| Global Warming Potential for | 3985 | ||||||||||||||||

| Carbon dioxide equivalent stage 1 (t) | 2.79 | ||||||||||||||||

| Refrigerant stage 2 | R23 | ||||||||||||||||

| Filling volume refrigerant stage 2 (g) | 680 | ||||||||||||||||

| Global Warming Potential for | 14800 | ||||||||||||||||

| Carbon dioxide equivalent stage 2 (t) | 10.064 | ||||||||||||||||

| External Pt100 sensor connection | integrated | ||||||||||||||||

| Digital interfaces | RS232 SD memory card USB Ethernet Modbus Alarm-out Optional: RS485, Profibus |

||||||||||||||||

| Analog connection input / output | Optional | ||||||||||||||||

| Ambient temperature | 5 ... 40 °C | ||||||||||||||||

| Dimensions W x L x H (inch) | 24.1 x 33.3 x 49.3 | ||||||||||||||||

| Weight (LBS) | 738.6 | ||||||||||||||||

| Sound pressure level (distance 1 m) max. (dBA) | 69 | ||||||||||||||||

| Process volume min. (active heat exchanger volume) liters | 9.5 (5) | ||||||||||||||||

| Internal usable expansion vol. (liters) | 7 | ||||||||||||||||

| Classification according to DIN12876-1 | Classification III (FL) | ||||||||||||||||

| Cooling of compressor | 2-stage Water | ||||||||||||||||

| Cooling water connection | G ¾‘‘ male with barbed fittings for tubing ½’’ lD | ||||||||||||||||

| Cooling water consumption (l/min) | 2…6 | ||||||||||||||||

| Cooling water temperature (°C) | <30 | ||||||||||||||||

| Cooling water differential pressure (bar) | 0.5 | ||||||||||||||||

| Available voltage versions | 3 x 208-230V/60Hz (+/- 5%) / 30A @ 208V, 33A @ 230V / Without Plug 3 x 230V/50Hz (+/- 10%) / 30A / Plug 63A CEE 3 x 400V/50Hz (+/- 10%) / 18A / Plug 32A CEE |

WHITEPAPER Optimal Temperature solution Click Here

WHITEPAPER Optimale Temperierloesung Click Here